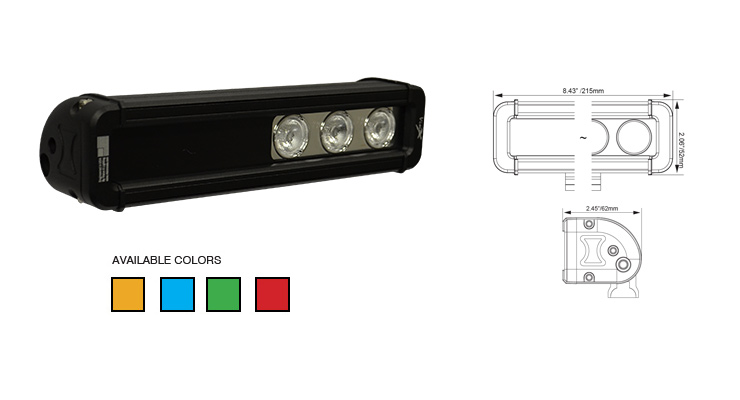

INDUSTRIAL LIGHTING!

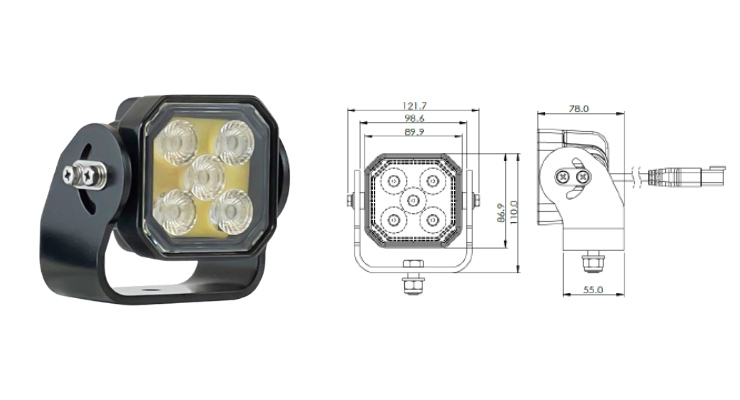

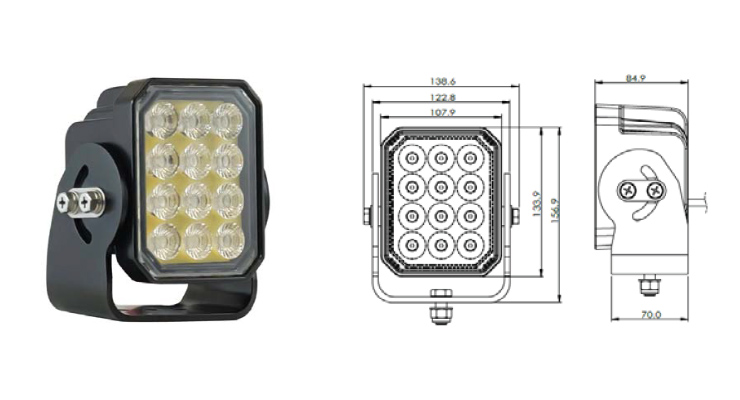

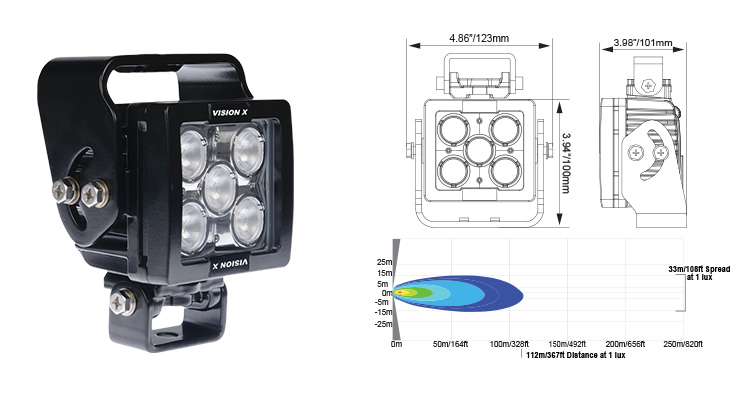

The Right Amount Of Light It's easy to bolt a light onto machinery and call it good, but only Vision X will work with you to create the ideal solution for your budget or project. Tested In The Harshest Environment Each Vision X light is put through countless tests to ensure it'll be able to get the job done, regardless of intensity.

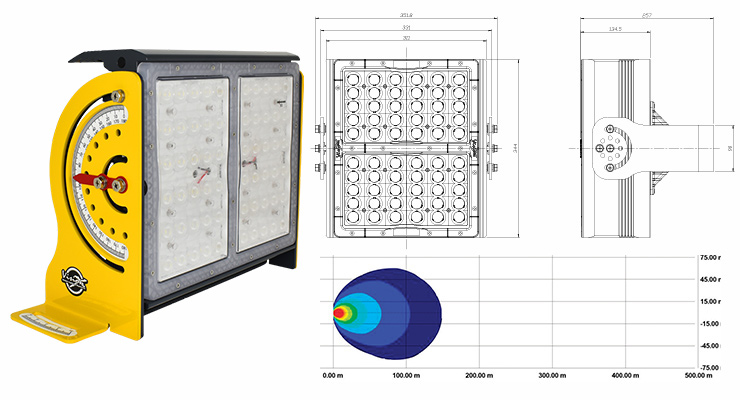

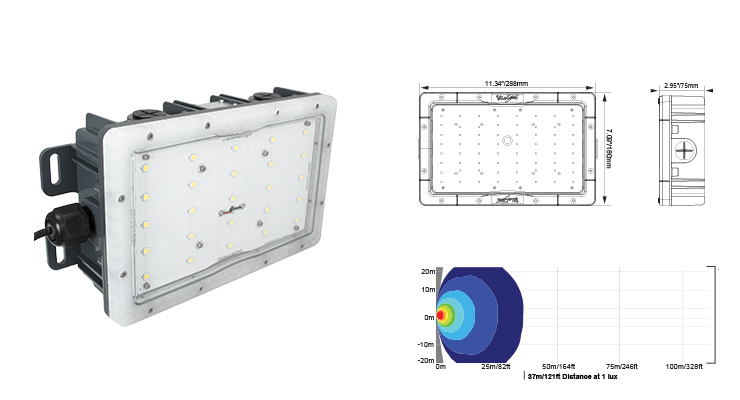

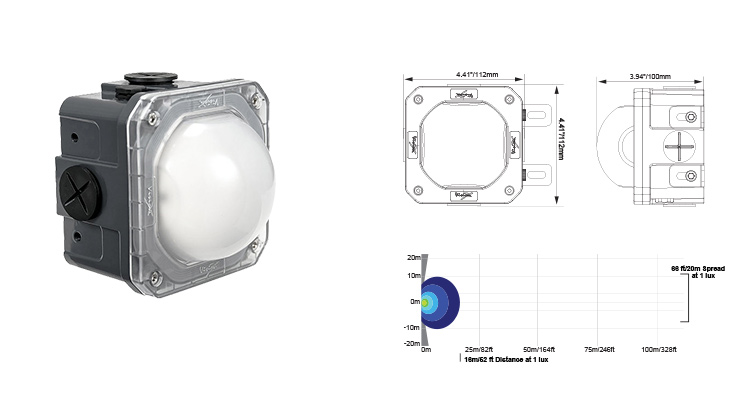

MINING INDUSTRIAL LIGHTING!

Mining Lights By Vision X is constantly evolving our product line by working with the world's leading LED manufacturers to drive LED lighting technology forward.

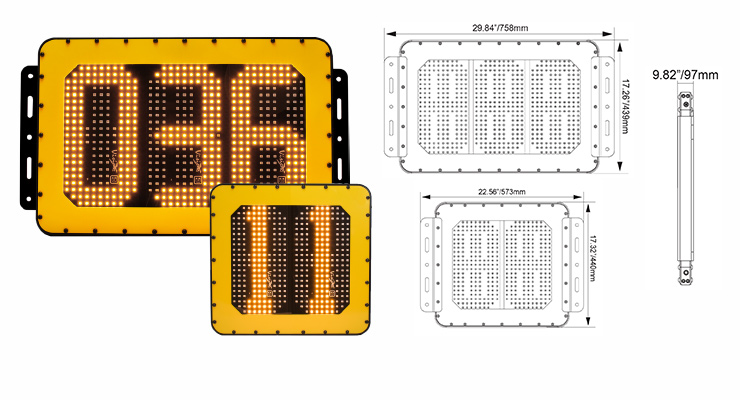

CREATING MINING SOLUTION!

Our lighting solution fit outs are configured to the exact needs of your site and equipment.Learn More